Flare Pilots

STACKMATCH manufactures Flare Ignition Systems to perform within your specific flaring application. Over the years we have developed a wide variety of Pilot & Ignition Systems, Electronic Controls and Accessories to meet and exceed your unique application requirements. Our Self-Aspirating Pilots, Forced Draft Flare Pilots and VacuTrack Pilots are designed for simple maintenance and safe operation.

Our Research, Development and Manufacturing Team is ready to tackle any difficult application you may presently face.

Hot Rod Flare Pilot

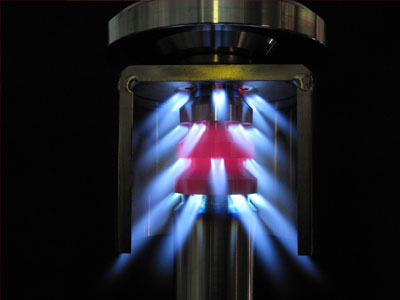

Hot Rod jet flame.

Hot Rod Flare Pilot

Hot Rod jet flame.

Hot Rod Flare Pilot

Hot Rod Aqua Shield Pilot Flame

Hot Rod Flare Pilot

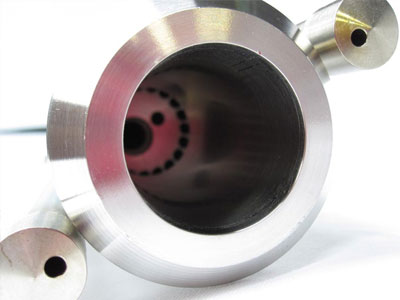

Hot Rod flame tip

Flare Pilot Applications

-

Portable Flares

-

Vertical Flares

-

Ground Flares

-

Pit Flares

-

Brine Pit Flares

-

H2S Flares

-

Compliance Flaring

-

Landfill Flares

-

Wet Gas Incineration Flares

-

Pipeline and Vent Flares

-

& many more

Hot Rod Flare Pilot

A unique self-aspirated flare pilot dedicated for flares with Stackmatch Flare Ignition, Inc. patented “Micro Flame Front Ignition“ and “Plasma Resonance Flame Detection“. The “Hot Rod“ flare pilot also provides a cost effective , safe reliable system. Stackmatch Flare Ignition, Inc. has designed a state of the art flare pilot that has proven effective in the most adverse conditions for flares.

Benefits of the Hot Rod Flare Pilot

-

Patented “Micro Flame Front Ignition“ (Providing Instantaneous positive ignition)

-

Patented “Plasma Resonance Flame Detection“ ( Providing instantaneous pilot flame verification for unmanned ignition)

-

Patented “Inverted Nozzle“

-

Quick start-up time

-

No additional operator adjustments are required

-

Minimal maintenance down time

-

Easier installation and safer for the operator than ever before

The “Hot Rod“ flare pilot has a patented “Inverted Nozzle“ that allows for extreme efficiency. The unique “Inverted Nozzle“ arrangement with a top and bottom diversion plate was designed to allow the spent nozzle gas to continuously clean the pilot nozzle, also protecting the nozzle cavity from contamination, should liquids or solids, be expelled from the flare. With the diversion plates strategically located, any gas escaping from the flare is forced to circulate between these plates. This circulating function allows for proper flare gas ignition even when the flare exit gas velocity is very slow or at a critical velocity. The internal nozzle cavity is engineered to provide a firmly rooted and highly protected flame configuration. Thus allowing proven pilot flame stability even when subjected to the most extreme weather elements.

The “Hot Rod“ flare pilots “Inverted Nozzle“ can be configured to meet your demands. The bottom diversion plate of the “Inverted Nozzle“ can act as a manifold which can output 2 or 3 separate by-pass jets fueled by a separate gas source. These by-pass jets can also be configured for a single entry tied together gas source.

Hot Rod Flare Pilots

Spitfire Flare Pilot

The “Spitfire“ flare pilot with Stackmatch Flare Ignition, Inc. patented “Micro Flame Front Ignition“ and “Plasma Resonance Flame Detection“ adds a cost effective, safe reliable system for any flare application. Stackmatch Flare Ignition, Inc. has designed a state of the art flare pilot that has been proven effective in the most adverse conditions for flares.

Benefits of the Spitfire Flare Pilot

-

Patented “Micro Flame Front Ignition“ (Providing Instantaneous positive ignition)

-

Patented “Plasma Resonance Flame Detection“ ( Providing instantaneous pilot flame verification for unmanned ignition)

-

Quick start-up time

-

No additional operator adjustments are required

-

Minimal maintenance down time

-

Easier installation and safer for the operator than ever before

The “Spitfire“ flare pilot is available in a 9 or 12 foot length depending on mounting and flame lick requirements. The “Spitfire“ flare pilot comes standard with Stackmatch Flare Ignition, Inc. patented “Micro Flame Front Ignition“ and“Plasma Resonance Flame Detection“and can be built to have a single (1) ordual (2) by-pass configuration. Also available on the “Spitfire“ flare pilot is a dual thermowell and flame front generator.

This pilot was designed with high temperatures and adverse environments in mind which is why we upgraded this pilot with a thick walled open throat nozzle to add even more life to the “Spitfire” flare pilot. The “Spitfire” flare pilot can be fitted witha “Spitfire” specific “Inverted Nozzle“ for a single (1) by-pass configuration. The internal nozzle cavity of both nozzles were engineered to provide a firmly rooted and highly protected flame configuration thus allowing proven pilot flame stability even when subjected to the most extreme weather elements.

The “Spitfire” flare pilot was designed to be a self-aspirating pilot but in the most adverse environments where contaminants and hurricane force winds are an issue the “Hybrid Purge“ air aspirating system can be utilized. By adding a clean pressurized air source to the “Spitfire“ flare pilot it can operate anywhere thus adding to the safety and reliability of the pilot.

Applications

-

Vertical Flares

-

H2S Flares

-

Enivormental Flares

-

Land Fill Flares

-

Storage Tank Vent

-

Portable Flares

-

Elevated Flares

-

Compliance Flaring

BPSF (Brine Pit Spitfire)

The “BPSF“ or “Brine Pit Spitfire“ flare pilot is a pilot designed for a saltwater contaminated atmosphere where a normal self-aspirated pilot would certainly fail. The “BPSF“ flare pilot uses a “Hybrid Purge” air-aspirating system which utilizes clean compressed air to feed the pilot when salt and othercontaminants are present. Our “BPSF“ flare pilot is not a pressurized pilot, but by adding compressed air to the “Hybrid Purge” canister it allows the air/gas mixing chamber of the pilot to self-aspirate and burn properly in the most extreme and contaminated conditions. The “BPSF“ pilot does require a clean compressed air source or will eventually fail if the pilots self- aspirating air supply is contaminated. Stackmatch Flare Ignition, Inc. has designed a state of the art pit flare pilot that has been proven effective in the most adverse and contaminated conditionswhere a pit flare is needed.

Benefits of the BPSF (Brine Pit Spitfire)

-

Patented “Micro Flame Front Ignition“ (Providing Instantaneous positive ignition)

-

Patented “Plasma Resonance Flame Detection“ ( Providing instantaneous pilot flame verification for unmanned ignition)

-

Quick start-up time

-

No additional operator adjustments are required

-

Minimal maintenance down time

-

Easier installation and safer for the operator than ever before

-

Made entirely out of stainless steel

“BPSF” or “Brine Pit Spitfire” flare pilot is available in a customer specified length and comes standard with Stackmatch Flare Ignition, Inc. patented “Micro Flame Front Ignition“ and “Plasma Resonance Flame Detection“which can also include a thermowell and thermocouple if required.

This pilot was designed with high temperatures and adverse environments in mind which is why we upgraded this pilot with a thick walled open throat nozzle to add even more life to the “BPSF” flare pilot. The internal nozzle cavity was engineered to provide a firmly rooted and highly protected flame configuration thus allowing proven pilot flame stability even when subjected to the most extreme weather elements.

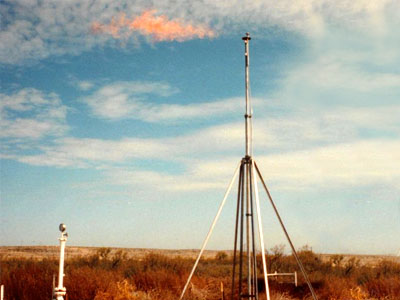

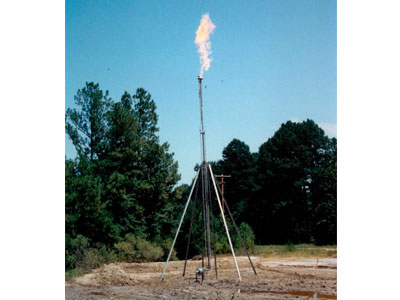

Pivoting Flare Stack

Stackmatch Flare Ignition, Inc. has an economical and cost saving answer to getting you in compliance with local government requirements pertaining to the safe, reliable combustion of vent gases from Storage Tanks, Glycol Dehydration and Amine Units, as well as all other small combustible vents.

Benefits of the Pivoting Flare Stack

-

Patented “Micro Flame Front Ignition“ (Providing Instantaneous positive ignition)

-

Patented “Plasma Resonance Flame Detection“ ( Providing instantaneous pilot flame verification for unmanned ignition)

-

Quick start-up time

-

All stainless steel design

Stackmatch Flare Ignition, Inc. has designed and manufactures a complete Flare System consisting of the Flare Tip, Self-Aspirating Pilot, Ignition System, Support Structure and Piping which is low cost and virtuallymaintenance free.

The Flare System addresses those venting applications where the gases to be burned have little or no pressure available. The flare creates a slight vacuumresulting in safely providing a media to evacuate and burn the vent gases.

The support structure is designed to allow the stack to pivot 180 degrees for access at grade of all components and connections including the flare tip and pilot for ease of inspection and maintenance.

The structure is completely made from 304 stainless steel. The bolted construction can be assembled by as little as two people in approximatly 4 – 6 hourswithout the necessity of cranes.

Cost Saving Benifits:

-

Minimal Capital Cost

-

No Foundation Required

-

Low Pilot Fuel Consumption

-

No Cranes Required For Erection

-

Minimum Maintenance & Inspection

-

No Painting Required

-

All Stainless Steel Construction

PHR (Pressurized "Hot Rod")

A unique flare pilot dedicated for flares with Stackmatch Flare Ignition, Inc. patented “Micro Flame Front Ignition“ and “Plasma Resonance Flame Detection“. The pressurized “Hot Rod“ flare pilot also provides a cost effective , safe reliable system. Stackmatch Flare Ignition, Inc. has designed a state of the art flare pilot that has proven effective in the most adverse conditions for flares.

Benefits of the PHR (Pressurized Hot Rod)

-

Patented “Micro Flame Front Ignition“ (Providing Instantaneous positive ignition)

-

Patented “Plasma Resonance Flame Detection“ ( Providing instantaneous pilot flame verification for unmanned ignition)

-

Patented “Inverted Nozzle“

-

Quick start-up time

-

No additional operator adjustments are required

-

Minimal maintenance down time

-

Easier installation and safer for the operator than ever before

The pressurized “Hot Rod“ flare pilot is a “Hot Rod” flare pilot with pressurized air. By adding a clean pressurized air source to the pressurized “Hot Rod” flare pilot it can operate anywhere thus adding to the safety and reliability of the pilot. The pressurized “Hot Rod” flare pilot has a patented “Inverted Nozzle“ that allows for extreme efficiency. The unique “Inverted Nozzle“ arrangement with a top and bottom diversion plate was designed to allow the spent nozzle gas to continuously clean the pilot nozzle, also protecting the nozzle cavity from contamination, should liquids or solids, be expelled from the flare. With the diversion plates strategically located, any gas escaping from the flare is forced to circulate between these plates. This circulating function allows for proper flare gas ignition even when the flare exit gas velocity is very slow or at a critical velocity. The internal nozzle cavity is engineered to provide a firmly rooted and highly protected flame configuration. Thus allowing proven pilot flame stability even when subjected to the most extreme weather elements.

The “Hot Rod“ flare pilots “Inverted Nozzle“ can be configured to meet your demands. The bottom diversion plate of the “Inverted Nozzle“ can act as a manifold which can output 2 by-pass jets fueled by a separate gas source. These by-pass jets can also be configured for a single entry tied together gas source.

Applications

-

Vertical Flares

-

H2S Flares

-

Enivormental Flares

-

Land Fill Flares

-

Storage Tank Vent

-

Portable Flares

-

Elevated Flares

-

Compliance Flaring